DIGITALISIERUNG IM ENGINIEERING

VIRTUELLE ERLEBNISSE GESTALTEN. DATENDURCHGÄNGIGKEIT SCHAFFEN. STANDARDS UND AUTOMATISMEN ETABLIEREN.

Digitale Unterstützung der Entwicklung

Das Engineering in produzierenden Unternehmen war schon in den vergangenen Jahrzehnten mit komplexer werdenden Produkten, mit einem höheren Softwareanteil und kürzeren Entwicklungszyklen konfrontiert. Viele Unternehmen haben daher neue IT-Lösungen implementiert, wie CAD-/CAE-Tools und Product-Lifecycle-Management (PLM)-Lösungen. In der Vergangenheit waren dies häufig Insellösungen in der Produktentwicklung. Eine integrierte IT-Landschaft und die durchgängige Vernetzung der Prozesskette sind im Zuge der Digitalisierung unabdingbar.

Weniger Kosten bei gleichzeitiger Prozessbeschleunigung

Dies erfordert von Unternehmen die Anpassung von Entwicklungsprozessen und -methoden sowie die Nutzung flexibler IT-Tools, die es ermöglichen, die Entwicklung digital zu unterstützen. Damit ist es möglich, den Datenfluss von Anfang an richtig aufzusetzen. Der Einsatz moderner Technologien, wie Virtual Reality und Augmented Reality, unterstützt Unternehmen zudem, Produkte in der frühen Entwicklungsphase realitätsnah erlebbar zu machen. Zusammenhänge werden besser sichtbar. Fehler in Design und Konstruktion werden frühzeitig erkannt. Iterationsschleifen werden reduziert. Die anschauliche Darstellung in VR/AR beschleunigt den Entwicklungsprozess und spart Kosten.

Unsere Schwerpunkte:

Wir von Feynsinn entwickeln für unsere Kunden Lösungen, die die Systeme unserer Kunden anwendergerecht unterstützen und die auf Ihre Anforderungen ausgerichtet sind.

Unser Leistungsspektrum

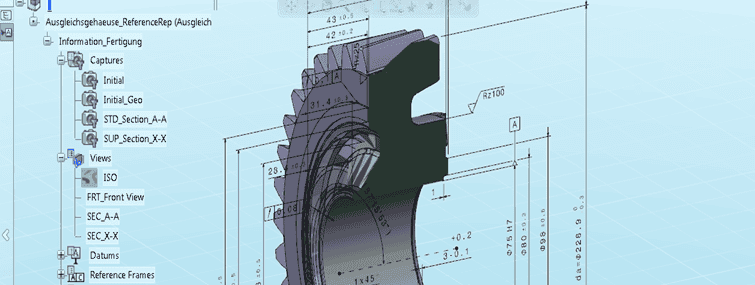

- Standardisierung und Automatisierung von Engineeringprozessen mit Catia und Siemens NX

- Vernetzung von Autorensystemen innerhalb der IT-Systemlandschaft durch Methoden und individuelle Softwarelösungen

- Unterstützung von Unternehmen in der Implementierung und Umsetzung von VR- und AR-Anwendungen für eine effektivere Planung und Analyse in der Produktentwicklung

Des Weiteren qualifizieren wir die Mitarbeiter im Umgang mit den CAD-Systemen und Daten.

Nutzen

- Engineering-Effizienz optimieren

- Prozesssicherheit maximieren

- Datendurchgängigkeit erzielen

- Entwicklungskosten reduzieren

- Entwicklungszeiten verkürzen

- Produktivität der Mitarbeitenden erhöhen

- Grundlagen für Industrie 4.0 schaffen

Toolkompetenz – CAx

- CATIA

- Prozesssicherheit maximieren

- NX

- 3D Experience Plattform

- Teamcenter

- Process Simulate

Toolkompetenz – Visualisierung

- 3DExcite

- Adobe Suite

- Autodesk VRED

- DeltaGen

- ESI IC.IDO

- Maya

- Nuke

- Unity3D

- Unreal

Leistungen im Detail

VOM KÖNNER ZUM MEHRKÖNNER - Erfolgsmomente mit Feynsinn

Etablierung der Strategie „Zeichnungsfreier Prozess“ in die Prozesskette im Fachbereich Entwicklung/Karosserie

Reduzierung des Konstruktionsaufwands und Erhöhung der Effektivität in der Entwicklung von Rotorquerschnittvarianten durch spezifische Airbus-Applikation.

Kundenspezifische Beratung, technische Einführung und Etablierung von Siemens bei Wefoma.

Die Einführung von Standards, spezifischer Applikationen & Schaffung eines zentralen Datenablage-Pools sorgt für höhere Produktivität und verbesserte Effizienz.

Jens Weiler

Leiter CA-Beratung