3D MASTER – PROZESSSICHERHEIT & VERBESSERTE DATENQUALITÄT

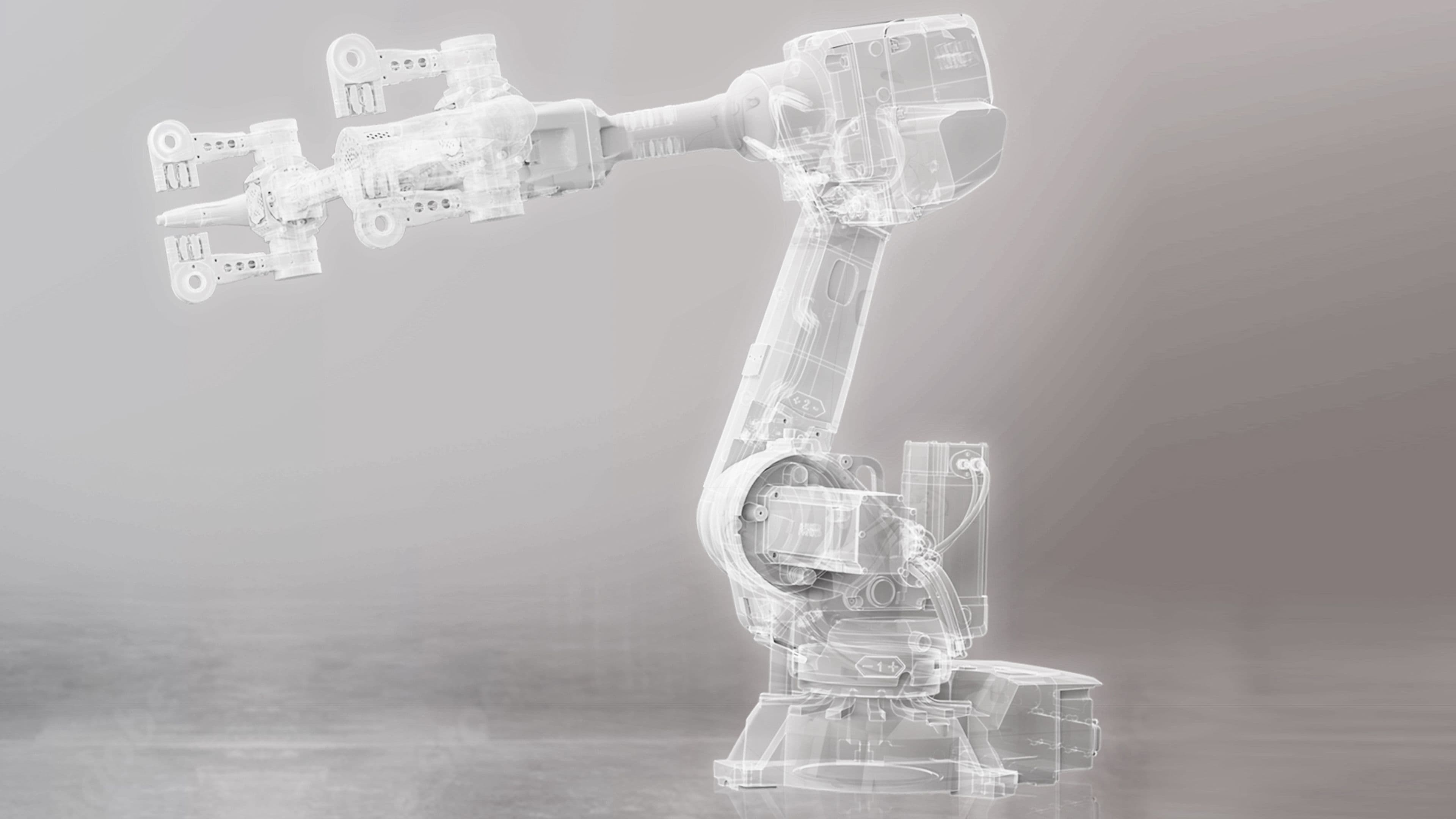

DER 3D MASTER – ZENTRALES MEDIUM IN DER VIRTUELLEN PRODUKTENTWICKLUNG

Was verbirgt sich hinter dem 3D-Master?

Der 3D Master kann das zentrale Medium in der Prozesskette darstellen, in dem Informationen hinterlegt und extrahiert werden können. Das Ziel des 3D Master ist es, alle produkt- und fertigungsrelevanten Informationen zu einer Komponente oder Baugruppe maschinenlesbar im 3D-Datensatz zur Verfügung zu stellen.

Die Basis bildet ein 3D-Datensatz, der zusätzlich zur Geometrie um alle notwendigen Informationen wie Funktionalität und Eigenschaften der Einzelteile und Baugruppen erweitert wird, die von den Folgeprozessen benötigt werden. Hinter dem 3D Master verbirgt sich kein Produkt, vielmehr handelt es sich um einen Prozess, der in der virtuellen Produktentwicklung inzwischen in vielen Unternehmen verwendet wird.

Schrittweiser Einsatz des 3D Master

Im ersten Step unterstützt der 3D Master dabei, die Prozesskette in der Verwendung von Daten auf die Methode „Single Point of Truth“ (SPOT) umzustellen. In der darauffolgenden Ausbaustufe wird ein „Single Source of Truth“ (SSoT) im Project-Lifecyle-Management-System (PLM-System) geschaffen. Dieses sieht vor, alle für die Prozesskette relevanten Formate bedarfsgerecht im PLM-System abzulegen. Die unterschiedlichen Formate sind wiederverwendbar.

Applikationen zur Vereinfachung des Konstruktionsaufwands

-

Create*Notes:

Die Appliaktion Create*Notes erzeugt in 3D unternehmesweit standardisierte Texte nach fest definierten Unternehmensvorgaben. Die Anwendung ist nützlich, um zusätzlich produkt- und fertigungsrelevante Informationen abzulegen.

-

FTA*Marker:

Die Applikation FTA*Marker kennzeichnet nach einem definierten Schema vom Anwender ausgewählte PMI in 3D. Die Anwendung ist nutzbringend, sobald Informationen in fertigungsrelevanter Form bzw. für die Prüfplanerstellung bzw. Messprotokolle erforderlich sind.

Wir von Feynsinn entwickeln und implementieren bereits seit mehr als 8 Jahren den 3D-Master-Prozess erfolgreich in Unternehmen unterschiedlichster Branchen. Dazu ermitteln wir zunächst die existierenden Prozesse im PEP (Produktentstehungsprozess) und leiten daraus eine Empfehlung ab. Stufenweise wird der für das jeweilige Unternehmen sinnvolle Einstieg in den 3D Master realisiert. Eine Erweiterung ist jederzeit möglich.

Nutzen 3D Master

- Der 3D-Master ermöglicht eine maschinengestützte Validierung, Auswertung (Arbeitserleichterung) und Produktion (Datendurchgängigkeit) durch die Erstellung maschinenlesbarer und semantischer PMI in 3D.

- Für die internen und externen Prozesskettenpartner werden relevante sekundäre Formate bedarfsgerecht und automatisiert erzeugt und im PLM-System abgelegt.

- Entwicklungszeiten können durch gezielte Implementierung von Automatismen bis zu 30 % reduziert werden.

- Der 3D Master sorgt für Prozesssicherheit durch Vermeidung von Redundanzen und verbesserter Datenqualität.

- 3D Master ≠ Papierlos. Sofern erforderlich, kann eine 2-dimensionale Darstellung freigaberelevanter Informationen auf Anfrage per Automatismus zu jeder Zeit aus dem 3D-Master erfolgen.

WissensWertes aus Theorie und Praxis

Jens Weiler

Leiter CA-Beratung